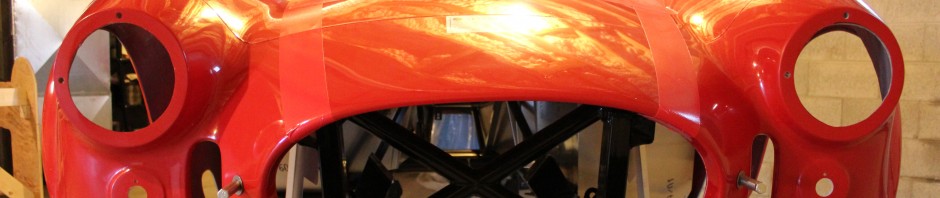

On May 19th I got the car over to Dave Dante. He wanted to do the initial body work with the body still on the chassis to make sue he got panel-panel edges and contours correct. I did a bit more work on the hood scoop opening and all panel edges, cost but mostly, advice it was Dave’s show. He re-filled and sanded and got things smooth. Two weeks later we removed the body so he could start spraying hi-build fillers and primers. I took the chassis home.

While Dave kept working on the body, recuperation I did more to start tying up the final steps on the chassis. I cut and soldered smaller gauge wires on the stereo speaker wires, although I may end up removing those.

I spent many hours just cleaning the entire chassis and parts. It was covered with dust from Dave’s work, a necessary but “dirty” evil. I re-worked the brake cylinder access cover panel in the driver footbox to simplify removal with the body on. I also determined where I thought the interference was for the windshield support arm and cut the opening larger on the driver side.

Next I did some cleaning and polishing of aluminum panels that will be installed with the final build. Now they are ready to go.

Next I did some cleaning and polishing of aluminum panels that will be installed with the final build. Now they are ready to go.

Now I started some work in the cockpit. I trimmed some insulation off the rear cockpit wall to help with the tight fit. I also then measured and cut all the pieces of insulation needed to cover the cockpit. I only glued some in place. I need to finalize the tunnel cover aluminum fit and fastening before the rest are put in permanently. I drilled access holes in the tunnel cover for sear heater and control wiring and installed grommets.

I needed to actually do some driving of the car, so I put in the driver seat belts seat and roll bar. I re-attached the side pipes and then took the chassis over to the local high school parking lot and just drove it around. I barely got past third gear and probably not above 40-45 mph, but I did a lot of hard turning and reasonably strong braking and acceleration. It all worked very well. I did notice one rattle, which I eventually traced to the side pipe bracket under the passenger door opening. I will deal with that at final build. Overall I was very happy with how everything worked.

I needed to actually do some driving of the car, so I put in the driver seat belts seat and roll bar. I re-attached the side pipes and then took the chassis over to the local high school parking lot and just drove it around. I barely got past third gear and probably not above 40-45 mph, but I did a lot of hard turning and reasonably strong braking and acceleration. It all worked very well. I did notice one rattle, which I eventually traced to the side pipe bracket under the passenger door opening. I will deal with that at final build. Overall I was very happy with how everything worked.

The next day I contacted Performance Products, the EFI manufacturer, to see if I could get some help with the problems getting the car started. We discussed the details and they had me make some adjustments to the Cold Cranking table, as well as a couple other things. After this was done I turned the engine over and it immediately started and idled beautifully. Hopefully, problem solved!

A couple days later I took it to a service center and had the wheels aligned. This also came out well.

In between I completed the cutting and installation of the trunk carpeting. This looks great. I also took a piece of carpeting to a carpet dealer and had the edge bound. This piece will cover the are of the battery box to hide the access cut-outs. I also later had this piece of carpet embroidered.

I put in the passenger roll bars again, and then properly drilled the upper bolt holes. With two bolts up top now I have a unique look !?!?

I put in the passenger roll bars again, and then properly drilled the upper bolt holes. With two bolts up top now I have a unique look !?!?

Next I began to look into putting on the tunnel cover. While doing this I noticed some greasy residue on the transmission support A-frame. I put the car on jack stands and checked underneath and it appears that transmission fluid is leaking out of the speedometer unit. I checked it and the O-ring looks good and the unit is fastened tight. I will have the investigate this further.

I decided to raise the steering whelk a it. I noticed with the adjustments to make the seat higher to fit over the body the steering wheel seemed a bit low. So I unfastened the pillow block and added some washers to bring it up a bit.

Then I removed the seat and began fitting the tunnel cover. I checked the shifter fit and had to enlarge the opening in that and the shifter fill plate to accommodate the shifter position and movement. I riveted the fill plate on the tunnel and drilled and riveted the tunnel in place. I also riveted the dash extension in place and fastened the support bracket to the firewall. I then put in the final pieces of insulation and began on the cockpit carpeting.

I followed the manual directions for installing the carpet. Some of the pieces fit perfectly, but most required trimming. Obviously, there was a need to trim where I made modifications, specifically the dash extension and the driver footbox punch-out areas. There was also trimming for e-brake, shifter and other areas. I tried to be very cautious

I followed the manual directions for installing the carpet. Some of the pieces fit perfectly, but most required trimming. Obviously, there was a need to trim where I made modifications, specifically the dash extension and the driver footbox punch-out areas. There was also trimming for e-brake, shifter and other areas. I tried to be very cautious when cutting so have spent many hours getting the pieces to fit.

when cutting so have spent many hours getting the pieces to fit.

I still have a bit to do with the carpet, and the body is almost finished and ready for the stripe color to be painted. I will post on that later. For more pictures, see the Gallery.

After returning from our extended vacation, link I needed to take the next steps on the body. I had Dave come by and give me a lesson on wet sanding. It was somewhat painful to have to do this. The paint looked awesome – the silver color was even nicer looking than I expected – so sanding it seemed wrong. But, click it is necessary to get ready for painting the stripes. Dave cautioned me about sanding around sharp curves and edges of the body and panels. He recommended putting tape around the edges while doing the flat surface parts, then removing the tape and lightly sanding those areas. I did this for most of the sanding, but eventually was able to sand without taping and just being cautious. I continued on this over the course of the next 10 days or so until all surfaces were completed. Very few flaws were seen anywhere on the body – Dave has done a great job so far.

Continue reading →

Continue reading →